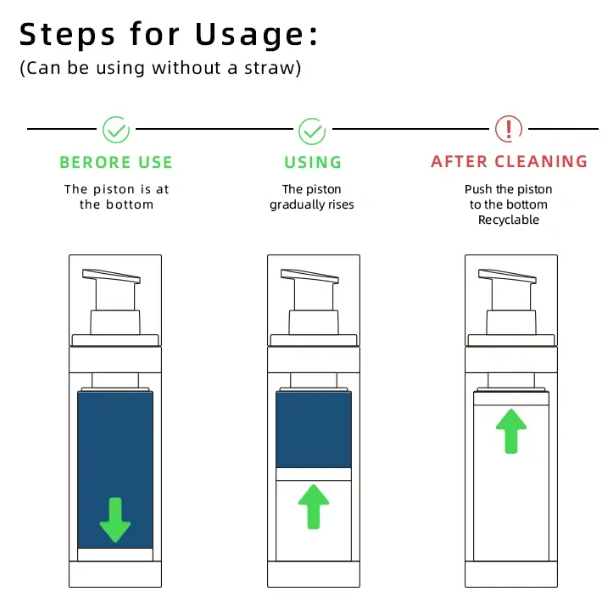

We often hear the term “airless bottle” in our daily life. So, what is a airless bottle? Airless pump bottles feature an internal diaphragm which houses a piston mechanism, with a small plastic disc that is placed at the base of the bottle prior to filling. As the pump is depressed by the user, the disc rises upwards, pushing the product up and out through the dispensing nozzle.

This differs in many ways from the dispensing process used by more traditional pump bottles. Standard pumps work by pulling the product from the base of the bottle through a tube. As the product is taken from the bottom, air gaps are formed at the top, exposing the remaining product to oxygen. In addition, as the tube does not reach all the way to the base, standard pump bottles can fail to perform optimally with low levels of product, and can create waste as not all the product can be drawn through.

When using airless pump bottles, the product is drawn from the top of the bottle, and as it is continually pushed closer towards the dispensing nozzle with each depression, waste is minimized and exact product doses can be administered with every use.This enables consumers to fully use up the product.

By keeping air out of the packaging, airless pump bottles also reduce the risk of product contamination, allowing for cleaner and more stable formulations. Airless pumps are normally utilized in different industries like cosmetics, pharmaceuticals, and food processing to fill products that need precise and controlled dosing.

Airless pumps are known for enhancing shelf life, lessening product waste, and offering a hygienic dispensing solution. They maintain product freshness and efficacy, making them a popular choice for luxury skincare brands.

Airless pumps allow for highly accurate and controlled dosing of skincare products, which is particularly crucial for products that need a precise quantity to be applied for the best results. This helps to prevent waste and ensures that the product is being utilized as intended.

In addition, airless pumps enable brands to create formulations with fewer or no preservatives, as the risk of contamination is significantly reduced. This has led to a growing demand for airless packaging in the skincare market.