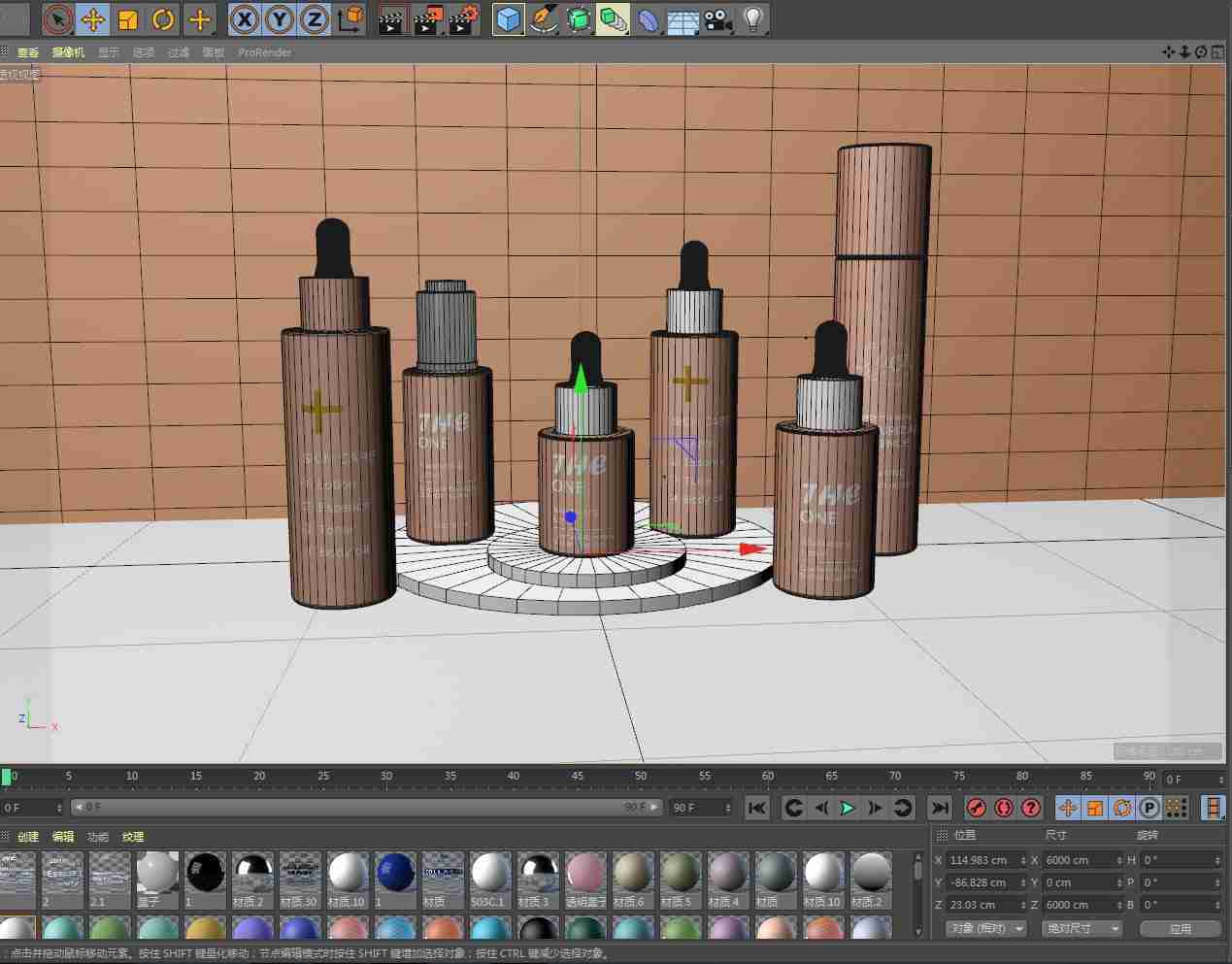

Design Drawings of the Product

From the customer’s idea and 3D drawing, we will discuss and assist in the silicone product design.

- Professional material selection advice

- Full understanding of the customer’s design, concept, and purpose

- Complete knowledge in designing custom silicone products according to applications

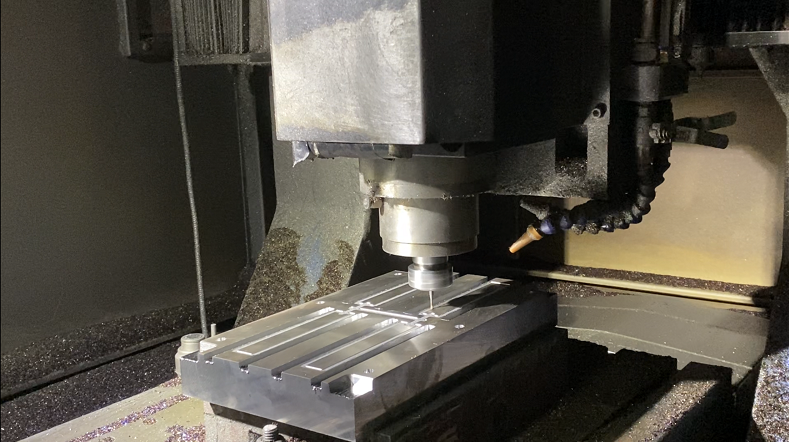

Proofing and Mold Developing

We will develop the mold first after the drawing and design are confirmed. Oulete will also provide samples to our customers. The purpose of mold development is to verify and assist the customer in understanding the product’s characteristics.

- Helps in saving you time and money

- Provides enough time for design adjustment and revisions

- 7-10 days of mass production of molds

Quality Control

Oulete has a strict quality control team to ensure that all our products are manufactured according to international standards.

- Checking the product to ensure that it is sampling qualified

- Provides quality control report

- Equipped with machines for gas tightness tests, firmness tests, and more

- Brief Introduction

- Advantages

Pantone Matching System matches and identifies color through its color standardization system. Pantone developed a numbering system for identifying colors and allowing the printer to match colors. The number system has three to four digits numbers with letters C, U, and M that stand for Coated, Un-coated, and Matte.

- Avoids color inconsistencies

- Helps in providing specific colors during the production

- Allows vibrant and a variety of colors to silicone products